Lithium battery Slitter

2020/12/11

![]()

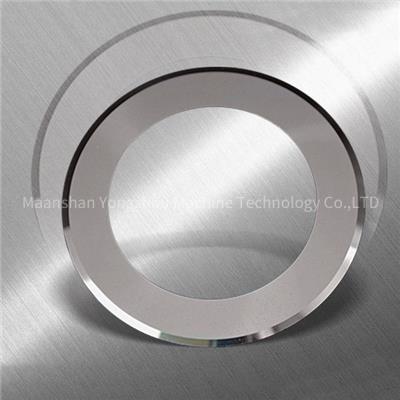

The cutting blade of lithium battery pole piece has good wear resistance and high machining precision. The round blade has high outer circle precision, and the edge needs to be strictly enlarged and tested. It is an ideal round blade for battery industry users to reduce cutting cost and improve cutting quality,

characteristic:

Compared with ordinary steel blade, the service life can be increased by six times at most, the blade replacement frequency is less, the production efficiency is high, the friction coefficient is low, the section is clean, and the loss of start-up and shutdown in the cutting process is less.

This series of circular slitting blades have good wear resistance and high machining accuracy. The outer circle of the blade is consistent and the edge is strictly enlarged and tested. The material cut by this series of blades is neat and smooth without burr.

The blade has the advantages of less replacement times, long service life and high cost performance. It is an ideal blade for users in the electronic battery industry to reduce the cutting cost and high cutting quality.

Production process of lithium battery slitting blade:

1. Pulping: special solvent and binder are used to mix with powdered positive and negative active substances respectively. After high-speed stirring, the paste like positive and negative polar materials are made.

2. Coating: the slurry is evenly coated on the surface of the metal foil, dried, and made into positive and negative electrode pieces respectively.

3. Assembly: put the battery in the order of positive plate diaphragm negative plate diaphragm from top to bottom. After winding to support the battery cell, and then through the process of injecting electrolyte and sealing, the battery assembly process is completed and the finished battery is made.

4. Chemical composition: use special battery charging and discharging equipment to test the charging and discharging of finished battery, and test each lithium battery, and screen out qualified finished battery for delivery.

Application range:

It is widely used in all kinds of electronic insulation materials (tape), battery positive and negative plate, battery diaphragm, carrier cover belt, metal foil, polarizing plate, plastic steel profile and other materials cutting and slitting equipment, and provides you with the regrinding service after each use, so as to prolong the service life of the blade.

- Related information

Maanshan Yongzhou Machine Technology Co.,LTD 版权所有 Wan ICP B no.2020021086 Disclaimer